Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

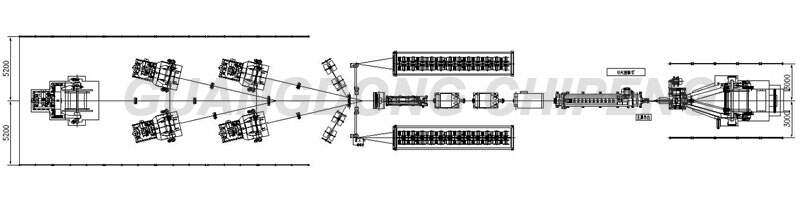

3150/5 drum twister machine

The 3150/5 Drum Twister Machine is a high-performance cable production line tailored for laying-up and armoring five-core large-section power cables. Engineered for enhanced productivity and control, it features automated PLC-based operation, an independent motorized system for each section, and versatile configuration for metallic and non-metallic shielding. This machine is ideal for advanced cable manufacturing applications that demand high precision, long length capacity, and high mechanical strength.

Product Features

Supports Complex 5-Core Cable Structures with High Precision

Designed specifically for 5-core insulated power cables, this model provides enhanced rotational balance and mechanical accuracy for large-diameter cables, supporting both round and sectoral cores.

Advanced Fault Monitoring and Online Diagnostics

Equipped with a smart touch screen and real-time diagnostics, the machine can detect and display fault types and exact locations instantly, significantly reducing troubleshooting and downtime.

Independent AC and DC Drive System for Each Process

The 3150/5 uses AC frequency-controlled motors for pay-off, armoring, taping, and caterpillar traction, while the take-up unit is powered by a high-torque DC motor. This ensures reliable operation and smooth speed transitions across various cable types.

Customizable Back Twist Function and Cable Pitch Settings

The drum-twisting structure supports adjustable back twist rates from 0% to 100%, while pitch values can be set, modified, and saved via the HMI. Operators can fine-tune process parameters to meet the most demanding cable configurations.

High-Capacity Armoring and Taping Integration

Compatible with dual-disc steel or non-metallic taping heads, the 3150/5 model supports synchronized taping and armoring with stable mechanical tension control, making it ideal for shielded power cables.

Technical Specifications

|

Model |

3150/5 |

|

Max Wire Diameter |

Φ25~Φ120mm |

|

Max Pay-Off Speed |

33 r/min |

|

Max Line Speed |

50 m/min |

|

Caterpillar Max Load |

4000 kg |

|

Back Twist Rate |

0-100% adjustable |

|

Take-Up Motor |

DC motor (Parker590 drive) |

|

Control System |

PLC + Touchscreen HMI |

Key System Components

Center & Rotating Pay-Off Units:

Motorized fork-type structure

Pneumatic tension control

Shaft-less bobbin clamping

Pneumatic brake with jog function

Compatible with crane-assisted bobbin loading

Double-Disc Taping & Shielding Head:

Applicable for non-woven, polyester, copper, and semi-conductive tapes

AC-driven with inverter control

Mechanical tension feedback ensures smooth application

Auto-stop on empty spool

Steel Tape Armoring Unit:

Half-split rotating design with pneumatic braking

Precise tension regulation across entire tape roll

AC motor control with left/right rotation functions

6T Rotating Caterpillar Traction:

Max pulling force: 6000 kg

Max line speed: 50 m/min

Max rotational speed: 33 r/min

37 kW AC frequency motor

Rotating Take-Up & Traversing System:

Fork-type rotating drum with DC drive

Shaft-less bobbin clamping, hydraulic lift platform

Max wire tension: 250 kg, jog-capable in both directions

AC-driven traversing system with adjustable pitch and directional auto-switch

Touch screen interface for all movement and pitch control settings